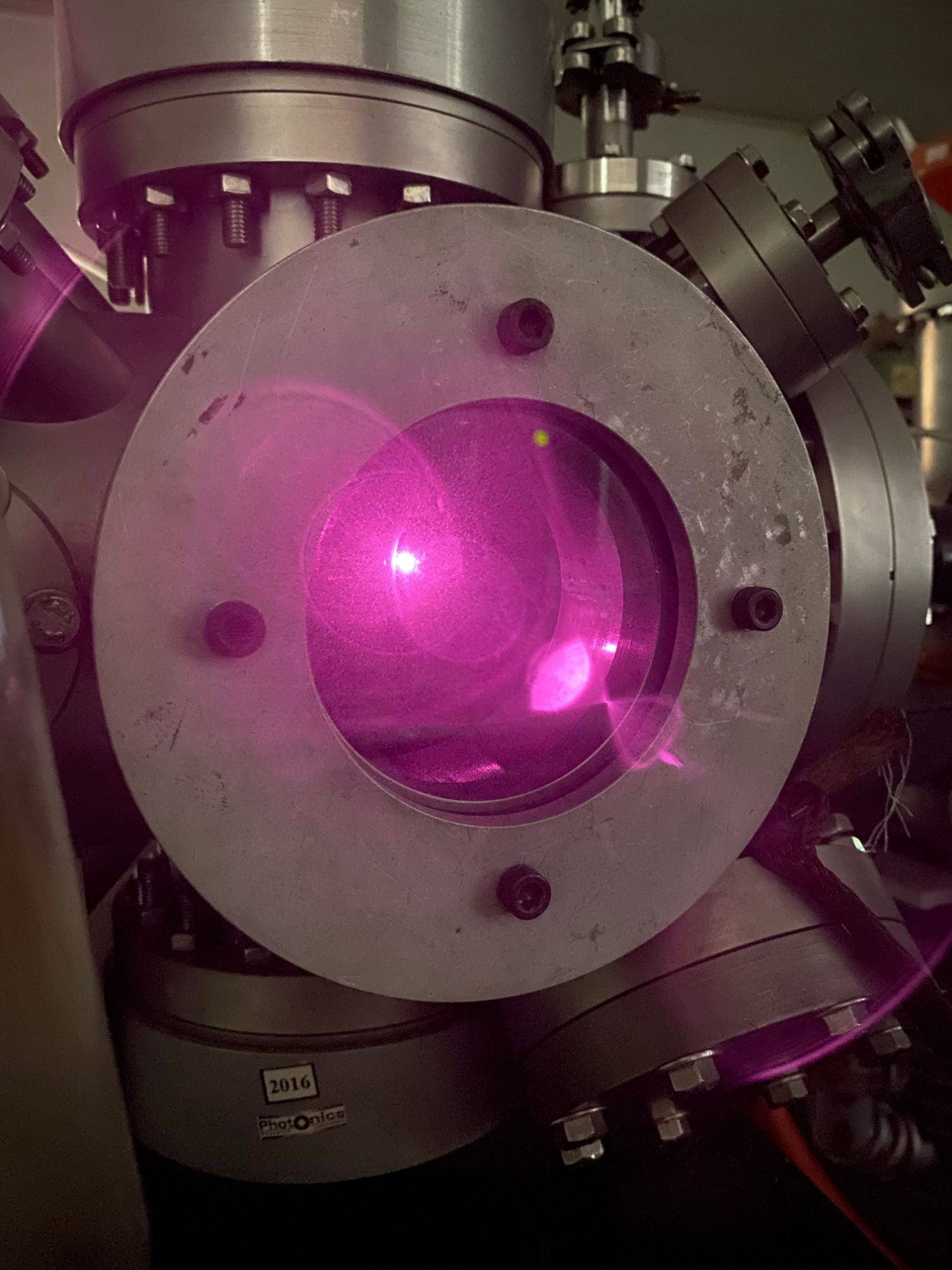

Scientists at the University of the Philippines – Diliman have developed a novel method for creating superconductor thin films. Using a low-energy femtosecond pulsed laser, they’ve explored a new approach to pulsed laser deposition (PLD). This differs from traditional methods employing high-energy nanosecond lasers.

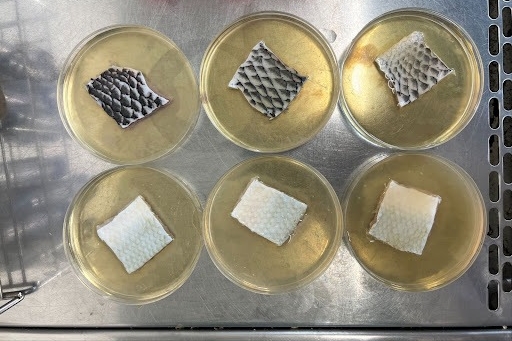

Joy Kristelle De Mata explained a key challenge: “A key challenge in this process is maintaining the stoichiometric ratio of elements in the film, as deviations can significantly impact material properties.” The team, including Dr. Lean Dasallas, Dr. Roland Sarmago, and Dr. Wilson Garcia, focused on BSCCO (bismuth strontium calcium copper oxide) thin films. BSCCO is crucial for applications in power cables, generators, and magnets.

The researchers varied background gas type and pressure to understand their effects on film composition and uniformity. De Mata noted their discovery: “Our results demonstrate that the background gas type and pressure significantly influence film composition.” However, they found that high-pressure fs-PLD didn’t perfectly replicate the original material’s composition. Existing computational models failed to predict these discrepancies, highlighting the need for improved models. De Mata added, “While fs-PLD offers advantages over nanosecond-PLD, achieving correct stoichiometry in thin films remains challenging, necessitating further optimization of deposition conditions.”

While promising, the technique isn’t yet ready for industrial-scale production. De Mata emphasized limitations: “Despite these challenges, fs-PLD remains a valuable technique for high-quality thin film fabrication in research and specialized applications.” The inconsistencies in film composition pose a challenge for mass production. Furthermore, the low-energy nature of fs-PLD slows the deposition process, increasing costs for large-scale applications. The team plans future research to refine existing models and investigate the effects of substrate heating.